Loose Belt Condition | Real-Time Monitoring

16/04/2025

16/04/2025

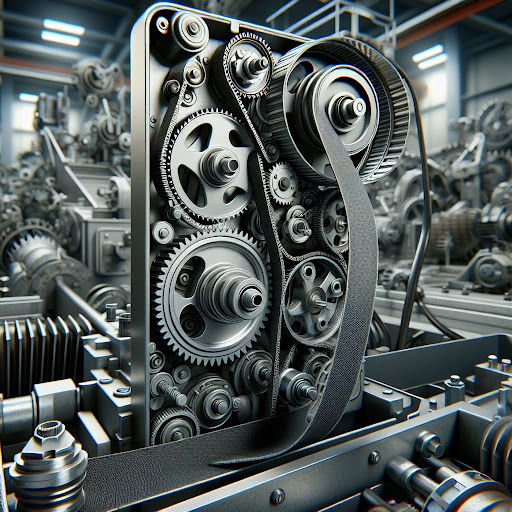

Loose Belt Condition

A Hidden Risk to Mechanical Systems

Understanding Loose Belt Condition

A loose belt in mechanical systems occurs when a belt loses tension, causing slippage between pulleys. Unlike a broken belt, a loose belt may still function but at reduced efficiency, leading to inconsistent performance and potential system failure over time. These conditions can lead to overheating, premature wear on components, and increased energy consumption.

A loose belt in mechanical systems occurs when a belt loses tension, causing slippage between pulleys. Unlike a broken belt, a loose belt may still function but at reduced efficiency, leading to inconsistent performance and potential system failure over time. These conditions can lead to overheating, premature wear on components, and increased energy consumption.

At Volta Insite, our InsiteAI technology offers real-time monitoring to detect belt tension issues early, preventing costly breakdowns and ensuring smooth operation.

Why Loose Belt Condition Is a Critical Concern

A loose belt can create several mechanical and operational risks, including:

Reduced Equipment Efficiency

Slippage decreases power transmission, forcing machinery to work harder and consume more energy.

Increased Wear and Tear

Loose belts lead to excessive vibration, causing premature wear on pulleys, bearings, and other mechanical components.

Risk of Unexpected Breakdowns

Continued operation with a loose belt can eventually lead to belt failure, resulting in unplanned downtime and costly repairs.

Overheating & Fire Hazard

Friction from a slipping belt can generate excessive heat, increasing the risk of overheating or even fire in extreme cases.

How InsiteAI Detects and Prevents Loose Belt Issues

Volta Insite’s predictive maintenance system continuously monitors mechanical performance to detect and diagnose loose belt conditions before they cause significant damage. Our solution includes:

Real-Time Belt Tension Monitoring

Continuously scans for irregularities in belt movement and tension, even in early stages of wear.

Advanced Vibration & Heat Pattern Analysis

Uses AI-driven analytics to detect subtle changes in vibration and temperature that indicate a loose belt.

Instant Alerts & Detailed Reports

Notifies maintenance teams immediately when a loose belt condition is detected, with precise location and severity details.

Preventative Actions with Volta Insite

By leveraging InsiteAI, facilities can:

✔ Detect loose belt conditions early to prevent costly system failures and production delays.

✔ Protect equipment by ensuring proper belt tension, reducing wear on key components.

✔ Enhance energy efficiency by eliminating unnecessary strain on machinery.

✔ Minimize downtime with proactive maintenance based on real-time data.

Safeguard Your Facility with InsiteAI’s Predictive Monitoring

Loose belt conditions may seem minor, but they can cause major disruptions if left unchecked. With Volta Insite’s advanced monitoring technology, you can proactively identify and address belt tension issues before they lead to costly failures. Contact us today to learn how InsiteAI can help optimize the safety and reliability of your mechanical systems.